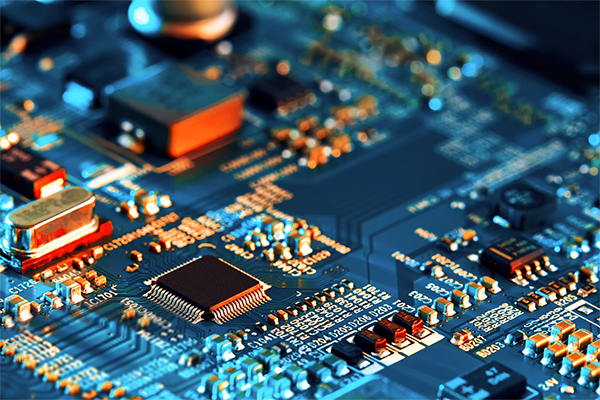

SemiConductor / Electronics

SemiConductor / Electronics

Semiconductors are used in integrated circuits, consumer electronics, communication systems, photovoltaic power generation, lighting, high-power power conversion and other fields. Whether from the perspective of technology or economic development, the importance of semiconductors is huge. Common semiconductor materials include silicon, germanium, gallium arsenide, etc., and silicon is the most influential one in the application of various semiconductor materials.

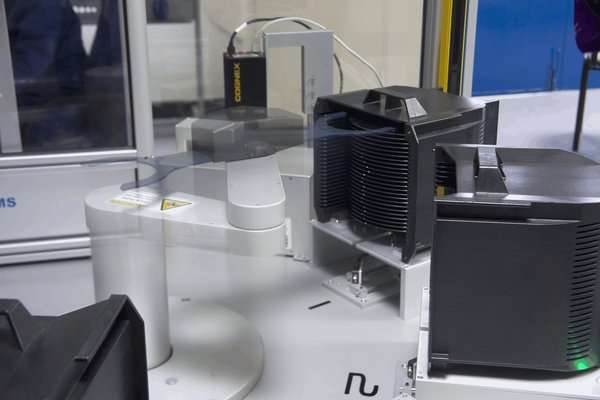

Wafer Sorter ☞

The wafer sorter can classify and group the produced wafers according to their size parameters such as diameter or thickness to meet the production needs of different products or processes; At the same time, defective wafers are screened to ensure that only qualified wafers enters the next step of processing and testing.

Testing Equipment ☞

In the production of semiconductor devices, dozens or even hundreds of processes must be experienced from semiconductor single wafer to final product. In order to ensure that the product performance is qualified, stable and reliable, and has a high yield, according to the production situation of various products, there must be strict specific requirements for all process steps. Therefore, corresponding systems and precise monitoring measures must be established in the production process, starting from the semiconductor process inspection first.