Lithium Battery

Lithium Battery

As a new type of secondary battery with high energy density, many cycles and long service life, lithium-ion batteries are currently widely used in mobile power supplies, electric vehicles, home appliances, smart wearable devices, 3C products and other fields, and have gradually become the main source of power for new energy vehicles and energy storage, and has attracted widespread attention from all walks of life.

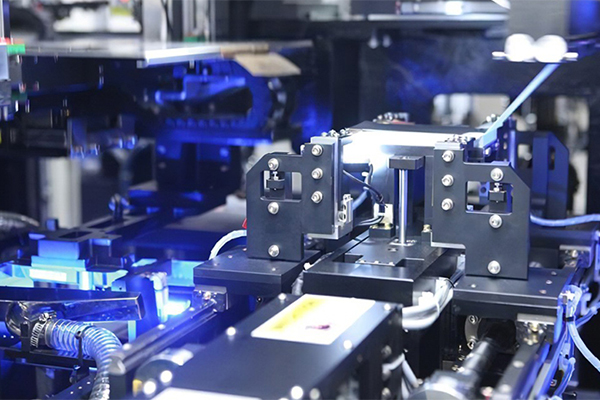

Stacking Machine ☞

The production machine is an essential process in the production process of lithium-ion batteries, and it is also a key process that directly affects the performance of batteries such as safety, capacity, and consistency. The production process is an automatic production equipment used to “wrap the pole ear, weld the pole ear, paste the insulation tape in the blank area of the pole ear, and finally roll the finished pole piece or cut the material” after the pole piece is cut. Reiter technology products can improve the accuracy of equipment operation and ensure that the pole sheet is stacked neatly, thereby effectively improving production efficiency and doing a good job of checking the next process.

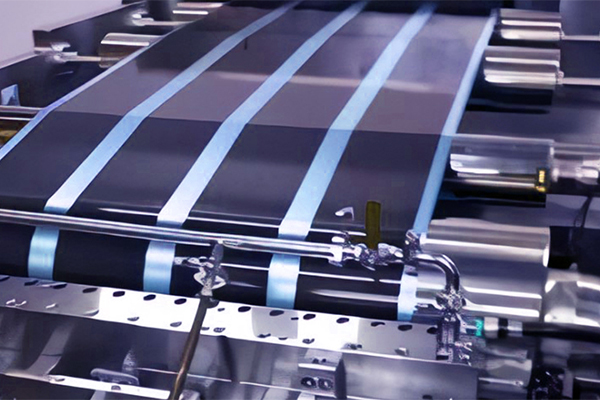

Coating Machine ☞

Diaphragm coating is the process of uniformly applying the positive and negative electrode slurries on the surface of the metal foil to form positive or negative electrodes. It is the most basic process in the front stage of lithium battery production. The coating machine runs at a fast speed and has high requirements for the control of each axis of motion. The products of Rite Technology meet the needs of customers, improve the stability and accuracy of the equipment, and help improve the competitiveness of the equipment.